There is farm content at the bottom of this post for those of you who are not interested in my current obsession with interfacing.

******

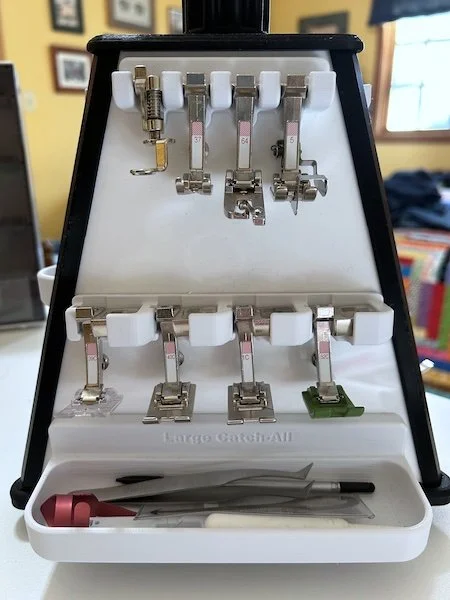

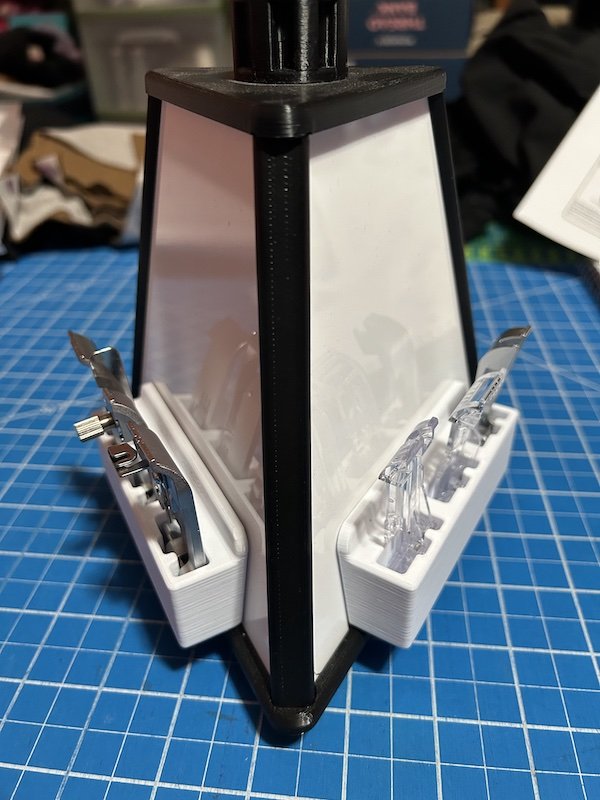

All of my class kits have been assembled, although OCD me will be going through them again this week to make sure nothing is missing.

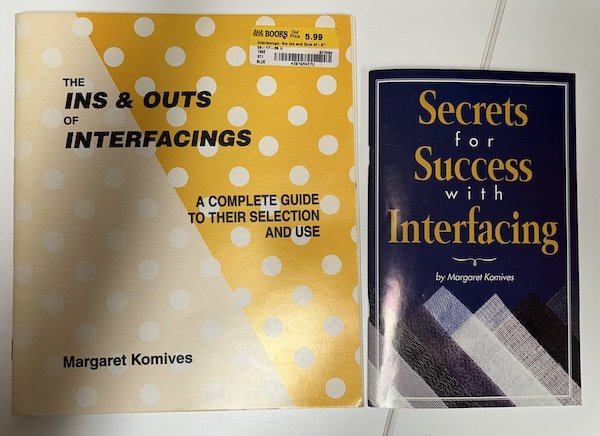

I am still stuck on the subject of interfacing. It has occurred to me that the topic of interfacing very much resembles the topic of finishing sweaters after one has knitted the pieces.

Knitting pattern: Assemble finished pieces of sweater. How? Sewing? Crochet? How do I do it neatly? What kind of sewing stitch do I use? What if the pieces don’t match? Is there something I should have done at the beginning to make this easier?

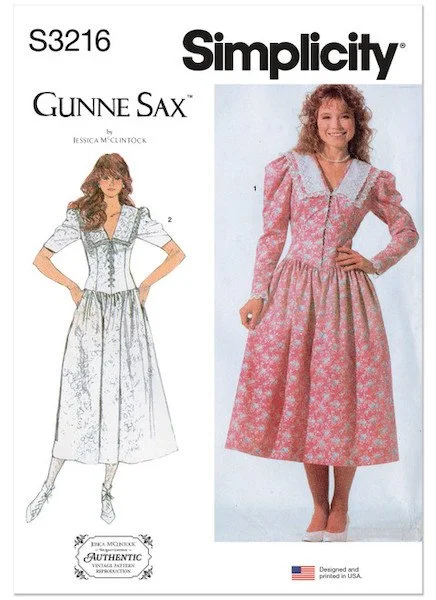

Sewing pattern: Fuse interfacing to fashion fabric. What is interfacing? What kind do I need? Should I just buy what’s at Hobby Lobby? How do I fuse? Why am I getting bubbles in the interfacing?

Back in 1996, I wrote a book about finishing knitwear that gathered in one place all of the information I painstakingly hunted down. I don’t have time to write a book about interfacing, although I am tempted.

You might say, “Well, this is 2026 and we have the internet.” Yes, but there is a tremendous amount of conflicting information on the internet. I have seen people advise not to use nonwoven interfacings in garments. I have seen other people swear by them. I have seen websites that insist that SF101 is the best interfacing for T-shirt quilts. I happen to disagree—I’ve got two class samples of knit interfacing fused to T-shirt fabric, one with the grainline of the interfacing running parallel to the grainline of the fabric and one with the grainline of the interfacing running perpendicular to the grainline of the fabric. If I were making a T-shirt quilt, I would use knit interfacing with the grainline running perpendicular to the grainline of the fabric, because it arrests the horizontal stretch of the T-shirt without changing the hand of the fabric. (I used a warp-insertion knit interfacing in that experiment.) Yet most of the interfacings I see recommended for T-shirt quilts are woven cottons. Is that because woven cotton interfacings are easy to find? I do not like the result when a stiff woven cotton is fused to T-shirt fabric.

[I need to experiment with that idea and quilt some T-shirt samples interfaced with knit interfacing, but my line of reasoning seems logical. And now I am wondering how that would affect embroidery on a T-shirt, if the area to be embroidered was interfaced before being hooped with stabilizer . . . Deana? Maybe you and I should try that when you’re here this summer.]

People tend to accept what they see on the internet as gospel. Just because someone posted a video on YouTube about something does not mean they know what they are talking about. AI is muddying the waters even further. What AI is doing at the moment is propagating information—correct or incorrect—through the universe at light speed. I think search engines are worse now than they were in, say, 2005.

I’ve also run across many books and websites that advise sewists to combine different types of interfacing to get a specific result. Great. Can you give some examples? I never see examples, except from the bagmakers.

This seems to be another example of a situation where people just parrot information they’ve heard before without stopping to examine it or verify assumptions. And there are a lot of assumptions. I asked the husband if this happens in traditionally male-dominated activities. Do hobby welders run into these kinds of information swamps? He said that he supposed it does.

I already had a lot of interfacings in my stash but I ordered more for this class. The problem with ordering interfacing—especially for newbie sewists—is that it’s hard to order online if you don’t know what you need to order. Joanns used to carry a fairly large selection of interfacings, and if you were lucky, you might run into a sales associate with some knowledge about the different kinds. Hobby Lobby carries interfacings, on bolts and in packages, but only the basics. Pellon has a whole line of what they call “luxury” fusibles, but I’ve never seen them in stores. Even online, some of these interfacings are hard to source.

Gah. I hate falling down these rabbit holes.

******

The husband and I have been dancing around a farm meeting for the last couple of days and we just need to sit down and have one. I got the chick schedule from the farm store—which already has chicks in stock—but we will wait to get some until after I get back from Sew Expo. I am leaning toward Lavender Orpingtons. They are very pretty birds: