Serger Hospital

A few weeks ago, my friend Edie asked me if I would look at her serger. She had taken it to a local service place but they hadn’t gotten around to fixing it (after more than a year). She retrieved it from them and brought it to me.

[Edie is Elaine’s cousin. A few days ago, I got a text from Edie’s niece asking me if I could teach her how to bind a quilt. Margaret (their aunt/great-aunt)—will be happy to know that the quilt she wants to bind is the yellow baby quilt from reunion. Amanda finished it. All of them belong to one of the families that founded our church. I laugh because I have more members of that family in my phone contacts than I do my own family. 🤪]

Anyway . . . I had to order another foot pedal for it because the original had gone missing at the repair shop. Fortunately, electronic foot pedals are cheap and plentiful. I have a whole box of them, but of course, I did not have one with the correct plug end. I ordered a replacement and it arrived yesterday. The husband was working late on a big concrete pour, so after dinner, I sat down to tinker with the serger.

I’m not sure if Edie took the machine in for service or if something was wrong with it. Nor do I know how she came into possession of it. (I should do a better job of getting information from my customers, LOL.) The machine is a Pfaff Hobbylock 788:

For all that I love my modern serger with all the bells and whistles, I have a soft spot for these vintage models—with the exception of the White Speedylock. That machine was designed by Satan himself. I suspect that the White Speedylock is the reason that sergers got a reputation for being difficult machines. I have one—given to me by someone who abandoned it in frustration—and I refuse to pass it along to anyone else because it is so awful to thread. And that’s coming from someone who can thread sergers in her sleep.

My plan of attack:

Find a copy of the manual. These are all over the internet.

Determine if the machine works at all. The loopers were still threaded, so I left them alone. I rethreaded the needles and checked to see if the machine would make a chain. It did, sort of. It wasn’t picking up the left needle thread. In 99% of cases, when a serger isn’t picking up a needle thread, it’s because the needle isn’t seated properly. In the other 1% of cases, it’s because the machine needs to be re-timed. I fervently hoped that 1% was not the reason the machine wasn’t picking up the needle thread because re-timing a serger is above my pay grade. I have re-timed sewing machines, but a serger is a different beast altogether.

Change the needles. This machine uses common household sewing machine needles, so I swapped out the existing needles for a couple of new 80/12 universals. I will say that the needle bar design on this machine leaves a bit to be desired. It took me a couple of attempts to get the needles in correctly.

Test again. This time, when I stepped on the pedal, the machine growled a bit, which reminded me that it probably needed oil. I checked the manual for the oiling instructions and oiled generously.

While rethreading the needles, I noticed that it was a bit tricky to get the left needle thread seated properly in the tension disks. I need to make Edie aware of that when I return the machine because that could be contributing to the problem. However, I was able to get the machine to make a chain with all four threads. Yay me.

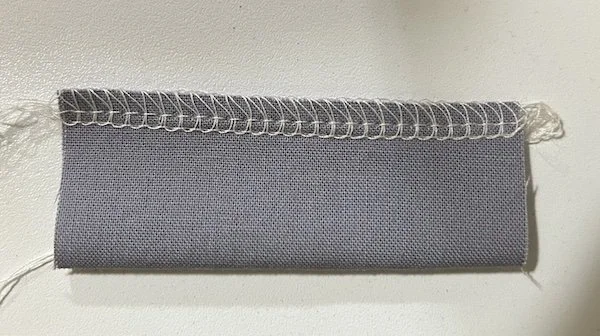

Test on a piece of fabric and refine the tension settings. The machine makes a lovely stitch:

I still want to go over the rest of it and test a few more settings and stitches, but I think this machine has many more years of life left in it.