Quilted Jacket Hell

All of this started because I thought the blue quilted fabric from Hobby Lobby would make a nice jacket . . .

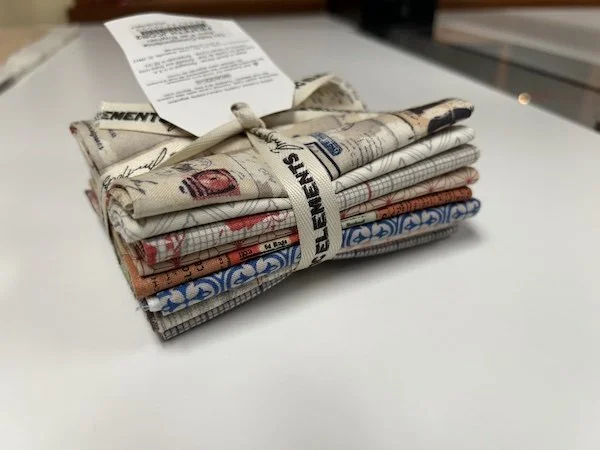

The store in Missoula would like a quilted jacket class. They carry Riley Blake fabrics, so the owner asked me if I would consider teaching this pattern:

Sure, why not. I might decide that I like it enough to make it up with the Hobby Lobby fabric. And if I am going to teach this pattern, I need to make it up so that I can locate any possible landmines for the students ahead of time.

On the surface, it looks like an easy pattern—two fronts, two sleeves, a back, and a collar. Edges finished with binding. The pattern calls for three yards of quilted 44" wide fabric. I don’t have time to quilt three yards of fabric for a jacket right now, so I bought some solid pink pre-quilted fabric from Joanns. It’s not of the best quality, but it worked for testing.

[When I finally use that Hobby Lobby fabric, it will be in a pattern that has been thoroughly tested.]

The pattern pieces are printed in four different colors on one large piece of paper. The pattern pieces overlap, so they have to be traced. There are no grainlines or notches. I traced the pattern and cut the pieces Friday afternoon and started working on this yesterday morning. I thought it might take me 3-4 hours.

Riley Blake has a video about making this jacket on their YouTube channel. I watched a bit of it before I got started. The process looked reasonable, although I wondered why they hadn’t shown the actual sewing of the shoulder seams. Then I tried to sew my shoulder seams.

The fronts were 2" longer than the back at the shoulder seams. Had I cut the pieces incorrectly? I got out the pattern and measured the pattern pieces. The fronts are 2" longer than the back at the shoulder seams.

I adjusted the fronts by cutting back the angle of the V-neck opening so that the shoulder seams matched, then sewed them. One nice feature about this pattern is that all of the inside seams are bound. The jacket is reversible. I was a bit puzzled by the fact that the pattern calls for two different widths of binding. The 1-1/2" binding is to cover the (bulky) inside seams, while the 2" binding is for finishing the outside edges, which are not bulky. I forged on and followed the directions as written. (The directions, by the way, are skimpy and poorly illustrated.)

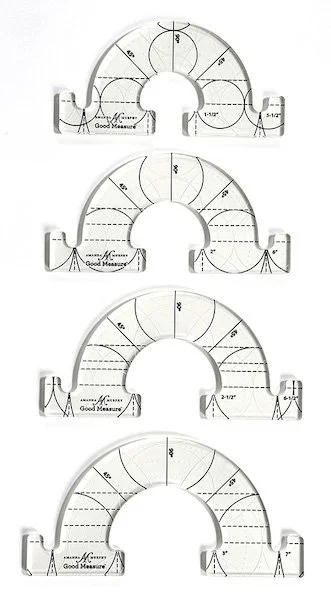

The 1-1/2" binding is folded in half lengthwise and pressed, making it 3/4" wide—or 6/8" for the math, as you’ll see in a moment. The seam allowances are 1/2" trimmed down to 3/8". After sewing the seam, the pattern instructions have you trim down the seam, then sew the binding along the seam. The pattern doesn’t specify that the raw edges of the seam and the binding should be aligned, although that was mentioned at one point in the video. After sewing the binding along the seam, the folded edge gets turned over the (very bulky) seam and topstitched down. It should look like this when it is done (oh how I love that #10 edgestitch foot):

Let’s do the math. The folded binding is 6/8" wide. It is sewn to a 3/8" seam with the raw edges aligned, meaning that 3/8" of the binding width becomes part of the seam, leaving only 3/8" to be folded over a very bulky seam—because the seam is two layers of quilted fabric!—and topstitched down.

I couldn’t make it happen. And I kept watching the video and thinking to myself that the binding they were sewing over the shoulder seam on their sample was wider than 3/8". From that point, in order to get that binding folded over and sewn down, I had to sew the binding on so that its raw edge was positioned below the raw edge of the seam by at least 1/8" and then trim the seam down even further.

This begs the question of why the narrower binding is specified in the pattern. It doesn’t work. The designer of the pattern is in the Riley Blake video and she says she prefers very tight binding, but this was ridiculous. I wonder if it’s a mistake in the pattern and the 1-1/2" binding was meant for the outer edge and the wider binding meant for the seams. The pattern clearly states to use the 1-1/2" binding for the seams, though.

It took me two hours to get those shoulder seams sorted out. I was able to get the sleeves attached and bound by lunchtime, although the instructions given in the pattern differ from the instructions that were given in the video. In the pattern, the binding is attached on the sleeve side of the seam and folded over to the body and stitched down. In the video, the instructions are to sew the binding to the body and fold it over to the sleeve side and stitch it down, which works much better.

And if I thought that trying to get that narrow binding folded over the shoulder seams was bad, trying to fold it over at the underarm on the side seam—where there are FOUR thicknesses of quilted fabric and two layers of sleeve seam binding—was next to impossible. I got a pair of very sharp, small scissors and trimmed that seam down to within an inch of its life.

Before I topstitched the side seam binding, I decided to attach the collar. The collar piece has to be bound on three sides with the wider binding. I did that, then began pinning the collar onto the jacket from the center back neck out.

The collar was an inch too long on either end, even after having cut back the angle of the V neck to get the shoulder seams to match. I went back to the pattern and measured. Yep, the collar pattern piece is longer than the measurement of the front Vs combined with the back neck.

Sigh. I did a bit more trimming to get the collar to attach to the body properly.

I was finishing up the topstitching on the side/body seam—which requires wrestling the jacket through the machine from one direction as far as possible, then turning it around and wrestling it through the machine from the other direction—when the husband came upstairs and asked me if I wanted to go out to dinner. I love that man.

All that is left now is to sew down the binding around the perimeter of the jacket and attach binding to the cuffs. I was hoping to have a photo of the completed jacket this morning, but it’s going to take another hour or two of work.

This pattern is currently unavailable on the Riley Blake website, although it says “coming soon.” I wonder if they had so many issues with sewists not being able to make the jacket as written that they are revising the pattern. The husband and I discussed this project on our way to dinner. He asked me why I hadn’t just ditched the pattern and made the jacket the way I thought it should go together. I said that if I am going to teach a pattern, I need to make it the way the designer specifies the first time, because the designer may have very good reasons for choosing certain techniques.

Believe me, I understand the work that goes into producing a quality pattern. Mistakes can creep in. On something this simple, though, many of these issues should have been caught in the testing stage. And I am a garment sewist. I suspect that a lot of the people who buy this pattern are quilters who don’t have a lot of garment-making experience. (That may be true of the designer, too.) This pattern is not a good introduction to garment sewing.

I still don’t know which pattern I’m going to use for that Hobby Lobby fabric. I have the Tamarack Jacket and the new McCall’s 8560 to test out. Neither of those patterns appears to have bound seams on the inside, at least from my initial reading. I don’t think it would be difficult to bind seams on either one, though, especially if I use binding of sufficient width. The bounds seams are a nice finishing detail.

We did go out to dinner, stopping by one of the jobsites on the way so the husband could check on a few things. This house is being built on the west shore of Flathead Lake. The views are stunning:

We couldn’t get a reservation at Mercantile Steak—our favorite date night restaurant—so we settled for Famous Dave’s, followed by a stop at Home Depot. The husband is going to put better lighting over my Juki 1541 in the garage so I can see what I am sewing.